WATER TREATMENT

Ecotechnol Water Treatment Technologies & Capabilities

Ecotechnol has considerable expertise in water purification and water treatment technologies, and the specialised process of Sea Water Reverse Osmosis (SWRO). Our team of experts will work with you to provide optimal water treatment systems tailored to suit your specific needs.

We are able to supply both fixed and containerised desalination systems, capable of transforming ground, brackish, or sea water, into potable water. Our systems are flexible, and are easily shipped, installed, and operated.

Multi-Container Sea Water Desalination

Our systems are flexible, and can cater to your specific needs. Our specialised desalination systems offer a multitude of features.

Our specialised desalination systems feature:

- Robust and reliable pre-treatment system

- Full and reliable automation

- High efficiency pumps

- An energy recovery device

- Remote monitoring

- Insulation, illumination and air conditioning

- Low energy consumption and very low maintenance costs

- A flexible, compat, modular design

- ISO 9001 : 2000

Sea Water Desalination Containerised Systems

Ecotechnol can supply both skid mounted, fixed desalination plants, as well as containerised desalination plants. We ensure only the highest quality components are used, including multi-step pre-treatment systems, energy recovery devices, energy efficient high pressure pumps and stainless steel construction and fittings (including exotic/duplex grades).

When the demand is for higher production capacities, Ecotechnol’s containerised sea water desalination units, can be connected to provide a simple, cost effective system. The systems are designed to be completely transportable, and include all external piping, pre-flanged, and ready for quick installation. The units can be supplied with additional ISO containers which serve as storage tanks.

Ecotechnol Desalination System Benefits

Our cost effective desalination systems have numerous additional benefits.

- Compact design – smaller footprint

- Higher production capacity / unit

- Lower weight – easier transport

- Robust and reliable pre-treatment system produces very high quality RO feed water

- RO membrane life is doubled due to high quality

- RO feed water reduced cleaning requirements – less backwashing, less waste, less cleaning chemicals

- Higher plant availability – more water produced

- Higher net water recovery

- Low energy consumption (<3 kWh/m3)

- Low chemical consumption

- More reliable & efficient operation

Transportable Water Treatment Systems

Ecotechnol can provide fully containerised, transportable systems to produce potable water from ground, brine, or sea water. These systems are ideal for remote sites such as mining camps, construction camps, exploration camps, holiday resorts, humanitarian & aid agencies.

Capacities (depending on water quality) for a single container, range from 50 or 100 persons up to 10,000 persons (in a single container). We can also supply multi-container systems which can supply over 250,000 persons or more.

Containerised Sea Water Desalination Capacities

Potable water production capacities from a single Ecotechnol ISO container treating sea water:

|

75 m3/day |

300 m3/day |

750 m3/day |

|

150 m3/day |

520 m3/day |

1000 m3/day |

|

220 m3/day |

600 m3/day |

1500 m3/day |

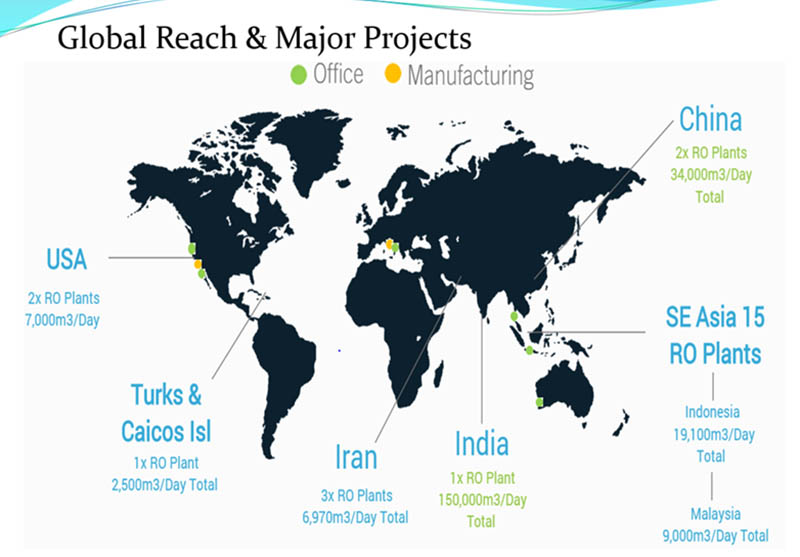

SWRO Equipment Installations – Globally

We have gained extensive worldwide experience in planning, designing, and implementing SWRO projects of various capacities for a wide range of industries and enterprises in diverse locations around the world.

Plant Installations: Sea Water Reverse Osmosis Systems – (SWRO)

We have an outstanding global reputation for our custom designed SWRO systems, providing various industries with the benefits and cost savings of these highly efficient systems.

Global SWRO Plant Installations

|

Customers |

Equipment |

Purpose |

|---|---|---|

|

Indonesia – PT. Putra Submer |

720 M3D SWRO |

Power Plant |

|

Indonesia – PT. Navatani Persada |

500 M3D SWRO |

Power Plant |

|

Indonesia – PT. Wijaya |

1200 M3D SWRO |

Power Plant |

|

Indonesia – GT Petrochem |

2000 M3D SWRO |

Chemical Factory |

|

Indonesia – PT. Budi |

2000 M3D SWRO |

Power Plant |

|

Indonesia – PT. Nagama |

3000 M3D SWRO |

Power Plant |

|

Malaysia – Shinyang Plywood 1, Miri |

500 M3D SWRO |

Power Plant |

|

Malaysia – Shinyang Plywood 2, Miri |

1500 M3D SWRO |

Power Plant |

|

Malaysia – Shinyang Plywood 3, Miri |

1000 M3D SWRO |

Power Plant |

|

Malaysia – Bitulu Foscom Plywood 1 |

2 x 500 M3D SWRO |

Power Plant |

|

Malaysia – Bitulu Foscom Plywood 2 |

500 M3D SWRO |

Power Plant |

|

China – Lee & Man Paper Dongguan |

24000 M3D SWRO |

Pulp and Paper Factory |

|

China – Guangzhou Paper |

10000 M3D SWRO |

Pulp and Paper Factory |

|

Iran – Aronab Co |

3 x 2000 M3D SWRO |

Refinery |

|

Iran – Fan Niroo |

400 M3D SWRO |

Power Plant |

|

Indonesia – Hydro Hitech Optima |

2 x 1400 M3D SWRO |

Power Plant |

|

Indonesia – PT. Jaya Benja Machine |

2400 M3D SWRO |

Power Plant |

|

Iran – Avin Palayesh Niroo |

570 M3D SWRO |

Power Plant |

|

Indonesia – Hydro Hitech Optima |

2 x 360 M3D SWRO |

Power Plant |

|

Indonesia – Hydro Hitech Optima |

2 x 140 M3D SWRO |

Power Plant |

Potable Water Production – Specifications for SWRO 750

Options include pre-treatment system with internal hydrocyclone and DAF / remote monitoring, or post treatment system with hypochlorite dosing or UV sterilisation.

See Detailed Specifications

|

Production |

750000 Litres per day |

Feed TDS < 45000ppm |

Product TDS > 500ppm |

|

Specifications |

|||

|

RO feed HP Pump |

904SS, multistage centrifugal |

Safety |

Start/Stop switch + motor overload protectors |

|

RO HP Pump Motor |

110kW with Soft Start |

Skid |

316 L SS |

|

Energy Recovery Device |

316L SS / Duplex 2205 Hydraulic Turbine |

Fittings |

HP – Duplex 31803 / 316 LLP – Eng grade plastic |

|

Pressure Vessels |

6 x FRP composite / 1000 psi max |

PLC |

Siemens or similar |

|

Membranes |

42 x Spiral wound/polyamide TFC > 99.2% salt rejection |

Automation |

Auto On/Off + electronic salinity controller |

|

Pre-Filtration |

Aquapure UF Membrane |

Instrumentation |

HP/LP, level, flow, conductivity |

|

Throttling Valve/Press Relief |

Max press/High pressure regulating valve |

Membrane Care |

Auto backflush / CIP Antiscalant Dosing |

|

Measurements |

12.5m(L) x 2.5m(W) x 2.9m(H) |

Tare Weight – 9000kg |

Gross Weight – 15000kg |

|

Connections |

Piping |

Feed inlet Product/Reject Outlet |

DN 150 DN 50 / DN 100 |

|

Feed pressure |

200 kPa (g) |

||

|

Electrical |

AC400 V; 3ph; 50 Hz |

Total installed power 133kW |

|

|

Operational |

Energy Consumption |

Total – 4.5 kWh/m3 |

RO – 3.5 kWh/m3 |

|

Chemicals |

Antiscalant Cleaning |

210 kg/month-NaOH/HCl |

Skid RO Desalination Plant – Saudi Aramco

Skid Mounted Reverse Osmosis on Ground

Skid Mounted Reverse Osmosis on Truck